Overview

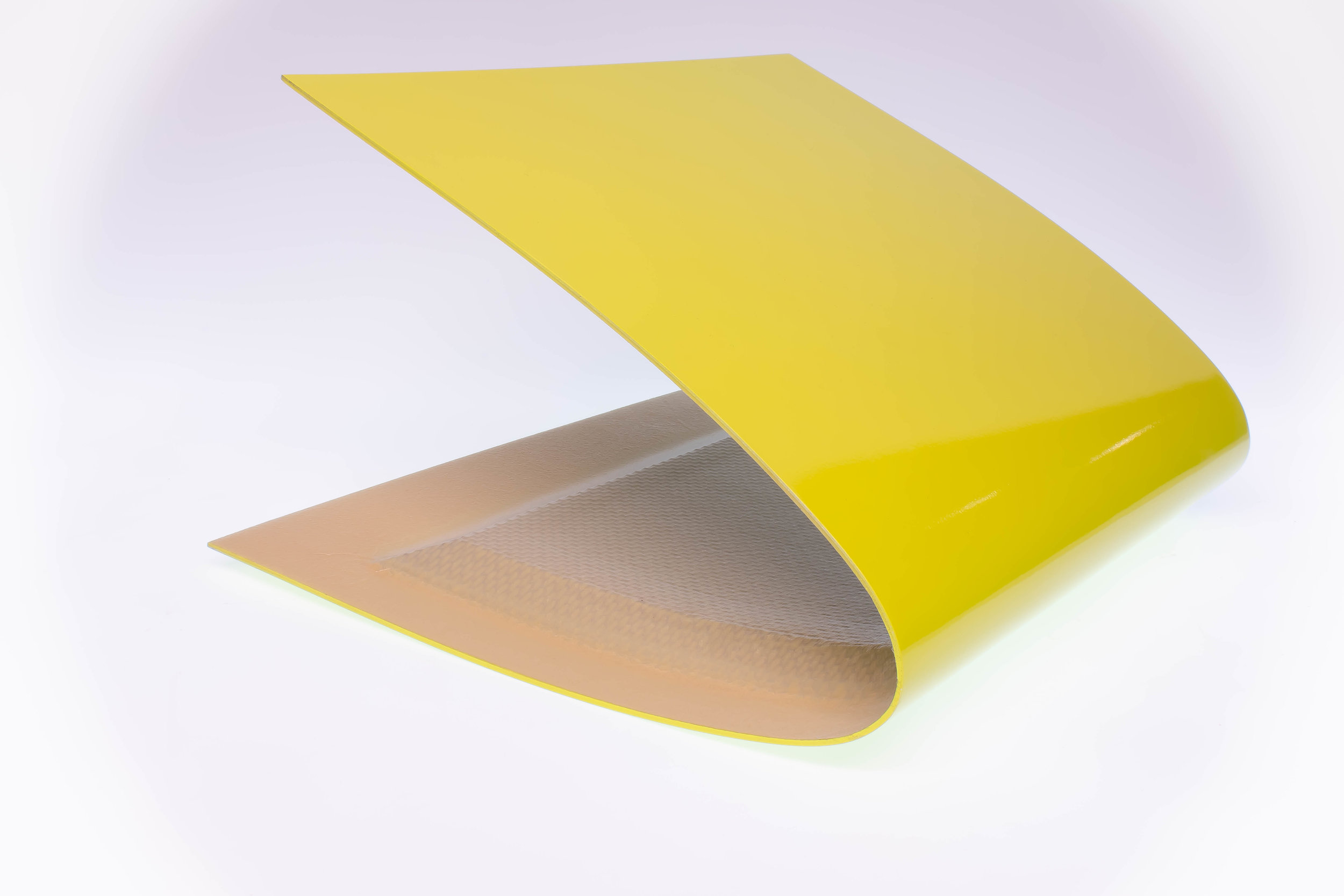

Our composite capabilities include autoclave bonding, compression molding and oven curing. We have a climate controlled clean room for lay-up and fabrication of bonded structures. We uphold superior quality to meet our customers needs and specifications. FOD prevention through all processes is key to the manufacture of these products.

Autoclave Bonding

Metal-Metal Honeycomb Bonded Structures

Fiber Reinforced Plastic Honeycomb Structures

Metal-Metal Bonded Structures

Carbon Fiber Laminate Structures

Kevlar Laminate Structures

Fiberglass Laminate Structures

8'x15' ASC Autoclave 450° F 150psi

NADCAP Composites Accredited

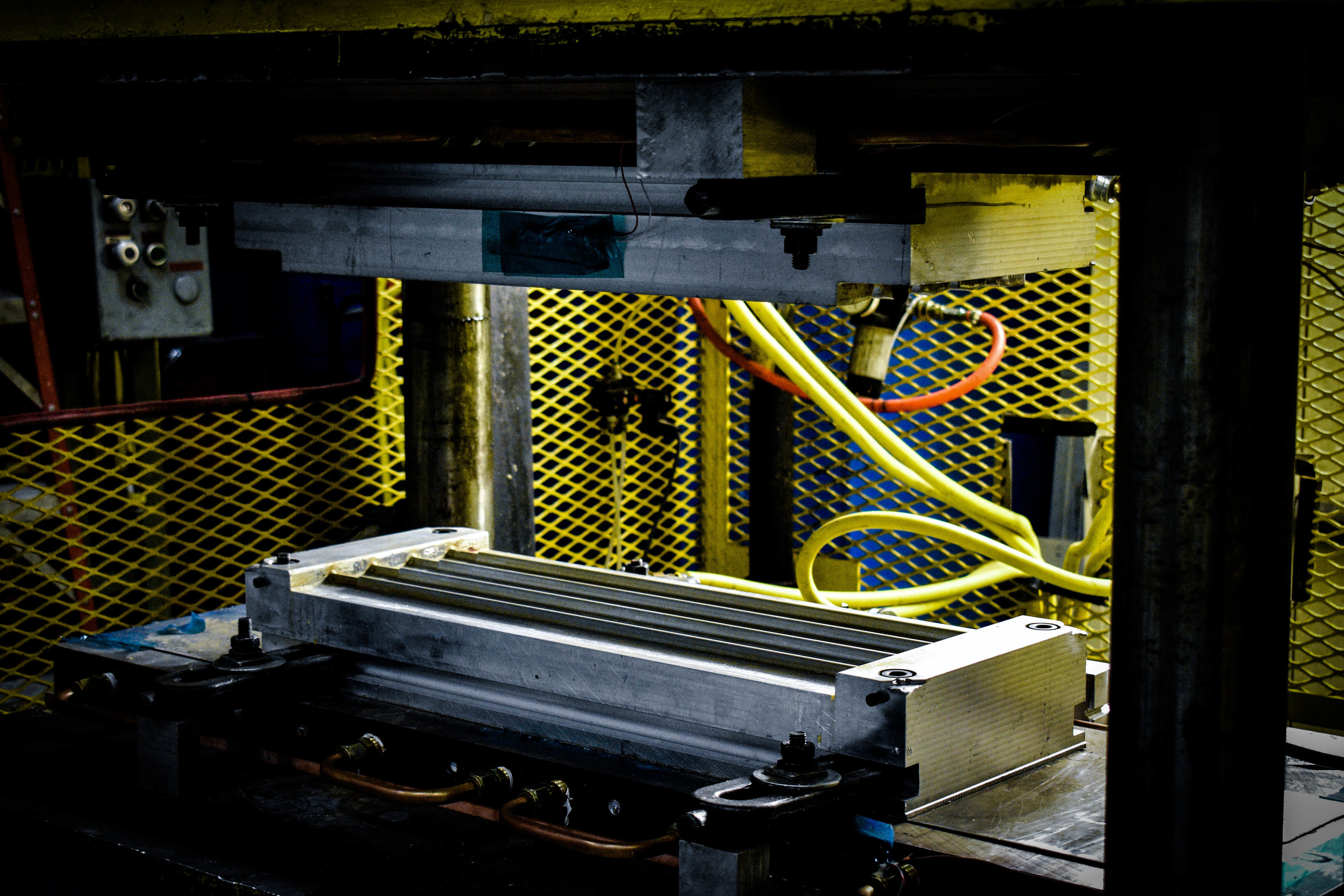

Compression Molding

Fiberglass, Kevlar, and Carbon Fiber impregnated with various resin systems.

Up to 400° F curing capabilities

(2) 50 Ton Greenerd Compression Molding Presses

150 Ton Rudel Compression Molding Press